When the bronze graphite sliding plate is in operation within the equipment, graphite will gradually separate out on the friction surface and form a lubricating film. This lubricating film can effectively reduce the friction coefficient and minimize the wear between the bronze matrix and other components. At the same time, the bronze matrix provides the necessary strength and load-bearing capacity to withstand the loads during the operation of the equipment.

Casting process:Centrifugal casting, sand casting, metal casting

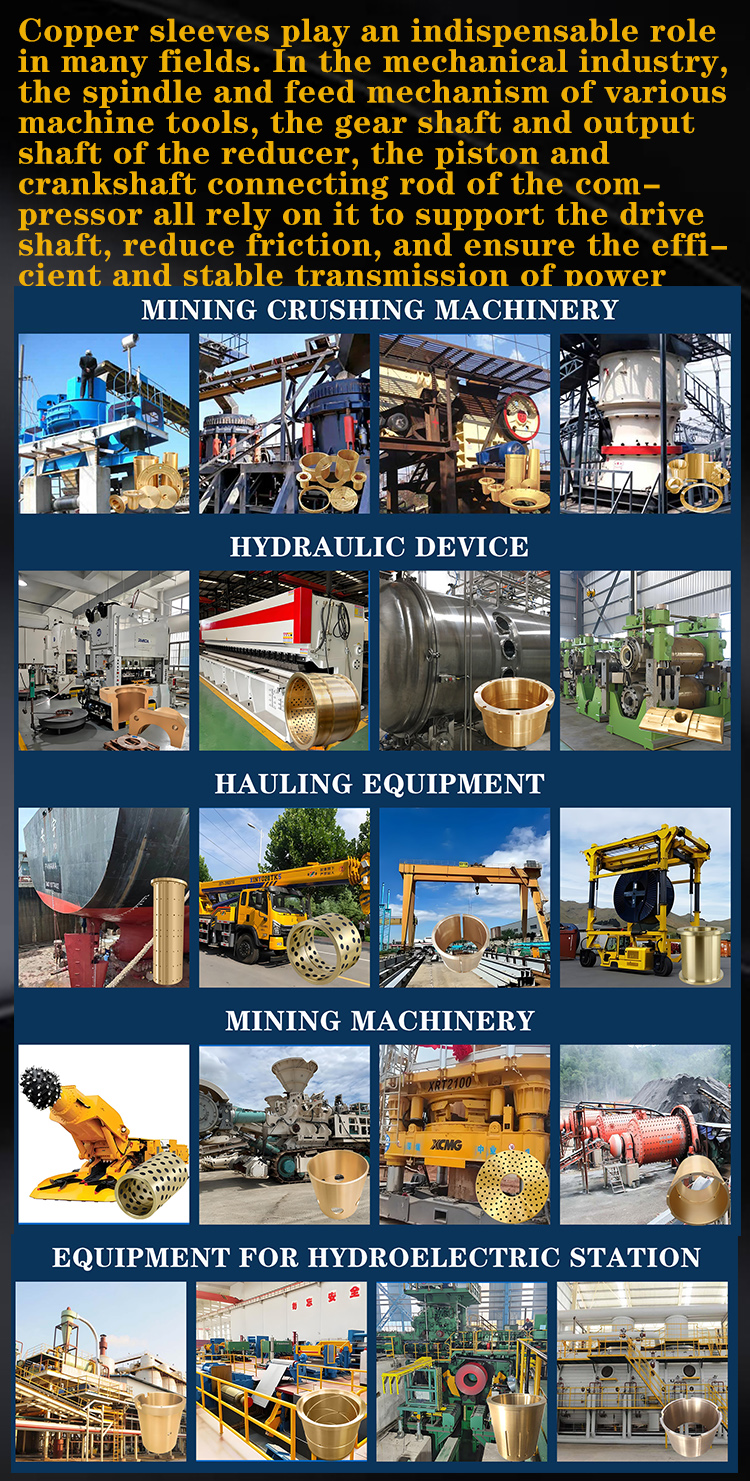

Application:Mining, coal mining, machinery industry

Surface finish:Customisation

Material:Customised copper alloys

.jpg)

.jpg)

.jpg)